If you are tired of seeing your favorite albums gather dust, I have good news for you — you can opt for outer and inner vinyl record sleeves and get peace of mind. Both types of sleeves do their best to prolong the life of your records. They ensure that the music and memories stay intact for years to come. But because there are many options on the market, you may have a hard time picking the one that will meet your needs.

In this article, I will ponder upon the various materials and sizes to help you make the right choice for your beloved vinyl collection.

Differences between outer and inner sleeves

Although both outer and inner sleeves share the common goal of preserving your vinyl records, their roles and functions differ.

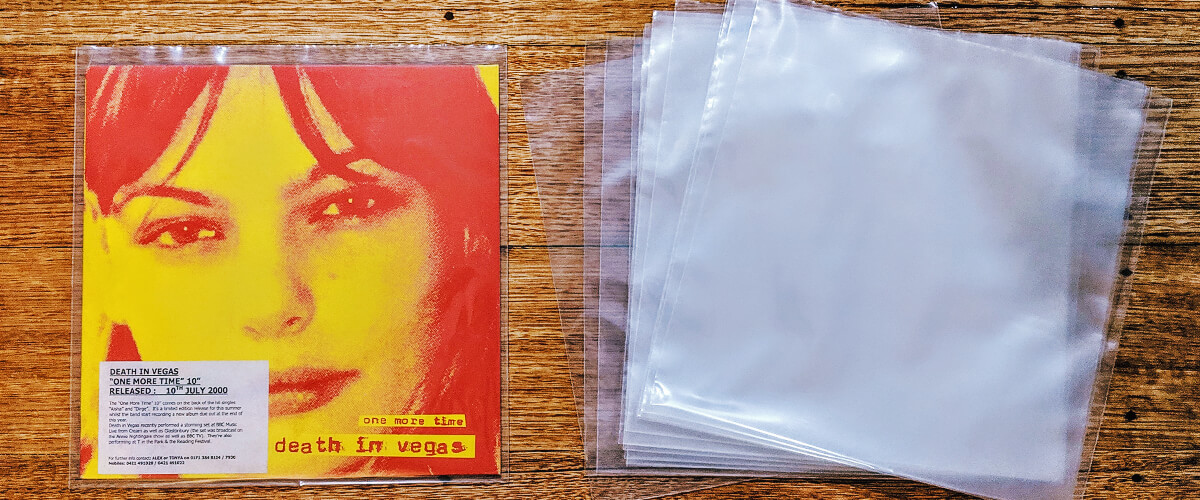

Outer sleeves envelop the entire record cover, including the album artwork. Their primary role is to protect the record cover and its contents from external factors such as dirt, dust, and moisture.

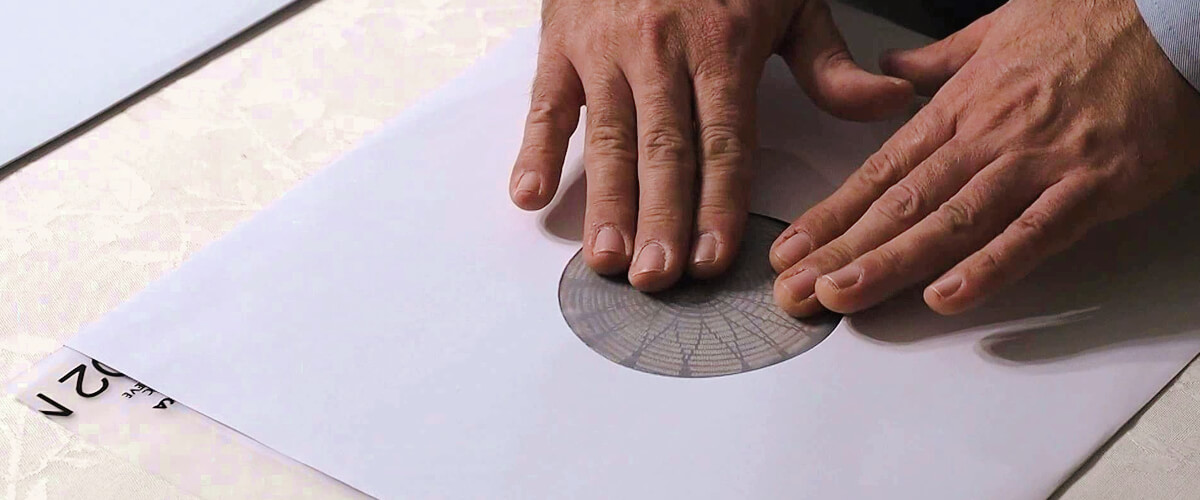

In contrast, record inner sleeves are designed to safeguard the vinyl record itself. They ensure a safe, snug fit inside the album cover, reducing the risk of damage from friction or impact.

Benefits of using sleeves

Enhanced protection

Outer and inner sleeves work together to shield your vinyl records from various forms of damage, such as dust, dirt, moisture, and scratches. This comprehensive protection ensures that your records stay in optimal condition, preserving both their sound quality and monetary value.

Improved organization

By using record cover sleeves, you can maintain a neat and orderly collection. Clear outer sleeves make it easy to identify records. While inner sleeves help keep the vinyl securely in place within the album cover, preventing accidental slips or disarray.

Reduced static buildup

Quality inner sleeves minimize static buildup on your records. This reduction in static not only enhances the listening experience but also prevents dust and debris from clinging to the vinyl surface.

Materials

Outer sleeve materials

PVC (polyvinyl chloride)

PVC record sleeves have been used in the past for both outer and inner sleeves. They are transparent, offering excellent visibility for album art. In addition to that, they are also quite durable and, therefore, deliver a good level of protection against dust, dirt, and moisture. However, they have fallen out of favor due to several concerns regarding their impact on vinyl records and the environment. The major concern with PVC sleeves is that they release chemicals over time, which can potentially damage the vinyl records they are meant to protect.

Polyethylene

Polyethylene is an affordable and lightweight material commonly used for outer sleeves. It offers basic protection against dust, dirt, and moisture. Though, it tends to be less durable and more prone to tearing or scuffing. Over time, these sleeves may also become cloudy or wrinkled, reducing the visibility of the album art.

Polypropylene

Polypropylene sleeves are more durable and clearer than polyethylene, offering better protection and visibility for your album artwork. They are also resistant to moisture and less prone to tearing. While they offer improved durability and clarity compared to polyethylene, polypropylene sleeves can be more expensive.

Mylar

Mylar, a polyester film, is the gold standard for record outer sleeves. It offers exceptional clarity, durability, and resistance to moisture, making it ideal for long-term protection and display purposes. But these record outer sleeves are the most expensive option, which may not be suitable for collectors on a tight budget.

| Material | Pros | Cons | Recommendations |

|---|---|---|---|

| PVC | Transparent and durable | Release chemicals that ruin the record and harm the environment | Opt for alternative materials like polyethylene, polypropylene, or Mylar for outer sleeves and poly-lined paper or HDPE for inner sleeves |

| Polyethylene | Affordable, lightweight, basic protection against dust and dirt | Less durable, prone to cloudiness and wrinkling | Suitable for tight budgets or less valuable records; for long-term protection, consider upgrading |

| Polypropylene | Durable, clear, moisture-resistant, less prone to tearing | More expensive than polyethylene | A great option for those willing to spend a bit more for better protection and visibility |

| Mylar | Exceptional clarity, durability, and moisture resistance | Most expensive option | Ideal for collectors who want the optimal protection and display option for valuable records |

Inner sleeve materials

Paper

Paper inner sleeves are the most affordable option. They are also widely available on the market. Though, these items can be abrasive to the record’s surface, causing scratches and generating static. Additionally, paper sleeves may deteriorate over time and can be susceptible to moisture damage.

Poly-lined paper

Poly-lined paper sleeves combine the affordability of paper with the added protection of a thin polyethylene lining. They are gentler on the record’s surface, reduce static, and provide better moisture resistance than plain paper sleeves. Although an improvement over the plain paper, poly-lined paper sleeves may still generate some static and offer less protection than HDPE sleeves.

Plastic or high-density polyethylene (HDPE)

Plastic inner record protector sleeves are usually made of HDPE. They provide the highest level of protection for your vinyl records. They are gentler on the record’s surface than the paper ones. Also, these options are more moisture-resistant and reduce static buildup more effectively. At the same time, HDPE sleeves are more expensive than other inner sleeve options like paper.

| Material | Pros | Cons | Recommendations |

|---|---|---|---|

| Paper | Affordable, widely available | Abrasive, generates static, moisture-prone | Not recommended due to potential damage to records |

| Poly-Lined Paper | Affordable, added protection, gentler on records | May still generate some static | A good compromise between affordability and protection, suitable for the novice collector |

| HDPE (High-Density Polyethylene) | Optimal protection, gentle on records, moisture-resistant, reduces static | More expensive than other options | Top choice for those willing to invest in quality sleeves for the finest preservation of records |

Sizes

Record outer and inner sleeves are generally designed to accommodate the most common vinyl record sizes, which include:

| Record Size | Sleeve Type | Sleeve Dimensions (approx.) | Commonly Used For |

|---|---|---|---|

| 7-inch | 7-inch Outer | 7.5 x 7.5 inches | 45 RPM singles |

| 7-inch Inner | 7 x 7 inches | ||

| 10-inch | 10-inch Outer | 10.5 x 10.5 inches | EPs, mini-albums |

| 10-inch Inner | 10 x 10 inches | ||

| 12-inch | 12-inch Outer | 12.5 x 12.5 inches | LPs, full-length albums |

| 12-inch Inner | 12 x 12 inches |

Remember that these dimensions are approximate and may vary slightly between manufacturers. Always double-check product descriptions and measurements to ensure you’re purchasing the right size sleeves for your records.

Also, consider any variations or irregularities in your collection, such as gatefold covers, double albums, or thicker records. Some manufacturers offer slightly larger sleeves to accommodate these unique cases, so read product descriptions and dimensions carefully.

Cleaning and maintenance

As you keep your record sleeves clean and well-maintained, you ensure the utmost protection for your vinyl collection and prolong the lifespan of both your records and their sleeves. Here are the things I recommend you do.

To clean outer sleeves

Remove dust and dirt. Use a soft, lint-free cloth or a record cleaning brush to gently wipe away any dust or dirt from the outer sleeve’s surface. Be sure to clean both sides of the sleeve.

For stubborn stains or smudges, dampen a soft cloth with a small amount of distilled water or a gentle record cleaning solution, and carefully clean the affected area. Avoid using harsh chemicals or solvents, as they may damage the sleeve material. Allow the sleeve to air dry completely before reinserting your record.

To clean inner sleeves

Periodically inspect your inner sleeves for signs of wear, damage, or excessive dirt buildup. If you find any issues, consider replacing the sleeve to prevent potential damage to your records.

If your inner sleeve is made of plastic, you can gently clean it with a soft, lint-free cloth or a record cleaning brush to remove dust and dirt. For poly-lined paper sleeves, it’s better to replace them if they become excessively dirty.

Sleeve replacement

Over time, sleeves can become worn, damaged, or excessively dirty. Replace outer sleeves when they become cloudy, wrinkled, or develop tears. Inner sleeves should be replaced if they are abrasive, accumulate too much static, or show signs of damage or excessive dirt.

The frequency of sleeve replacement depends on how frequently you handle your records and the overall condition of your sleeves. A general guideline is to replace inner sleeves every 3-5 years or sooner if you notice any signs of wear or damage. Outer sleeves may last longer, but monitor their condition and replace them as needed.